In AI hardware design, aluminum and carbon materials are often considered together. But how do engineers determine when to stick with aluminum, and when it makes sense to selectively use carbon materials? This is a question of engineering feasibility, not marketing hype. This article clarifies the boundaries between aluminum and carbon, helping engineers make rational choices in aluminum AI hardware structure and hybrid aluminum carbon design.

Note: We discuss feasibility and engineering logic, not mass production promises.

1️⃣ Aluminum as the Structural Baseline

Aluminum has long been the baseline structural material for AI hardware. From server chassis and heat sinks to support frames, aluminum defines geometry, dimensional tolerances, and load paths.

- Extrusion and Machining: Aluminum can be extruded into complex profiles and machined with high precision for threads, holes, and other assembly features.

- Assembly Consistency: AI hardware demands precise positioning, thermal paths, and electrical connections. Aluminum’s predictability ensures consistent assembly outcomes.

- Deterministic Material Behavior: High-performance servers and compute nodes tolerate very low structural risk. Aluminum’s predictable fatigue, strength, and thermal expansion behavior make it difficult to replace completely with carbon-based materials.

Simply put, if shape and load-bearing are the core functions, aluminum is the default “first choice” for structure.

2️⃣ What Carbon Materials Actually Do Well

Carbon-based materials (graphene, carbon fiber composites, conductive carbon fillers) are better suited as functional enhancement layers, rather than primary structural components.

Key areas where carbon materials excel:

- Electrical Conductivity: Useful for local electrical paths or grounding solutions.

- Thermal Spreading: Carbon layers can enhance local heat dissipation to aluminum heat sinks, without replacing the main thermal structure.

- EMI Shielding and Surface Functionality: Carbon coatings or fillers improve electromagnetic interference shielding and signal integrity.

- Weight Reduction in Non-Load-Bearing Parts: Carbon composites can help reduce weight in areas not critical for structural integrity.

The core message: carbon materials add functional value, not structural replacement.

3️⃣ The Real Engineering Boundaries

Engineers appreciate a clear comparison. The table below illustrates the strengths of aluminum vs carbon in AI hardware contexts:

| Dimension | Aluminum | Carbon Materials |

|---|---|---|

| Load-bearing | ⭐⭐⭐⭐⭐ | ⭐ |

| Dimensional tolerance | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Scalability | ⭐⭐⭐⭐⭐ | ⭐ |

| Functional enhancement | ⭐⭐ | ⭐⭐⭐⭐ |

- If the core function is load or precision → Aluminum first

- If the function is performance enhancement → Carbon selectively

This illustrates the principle of primary structure vs functional layer.

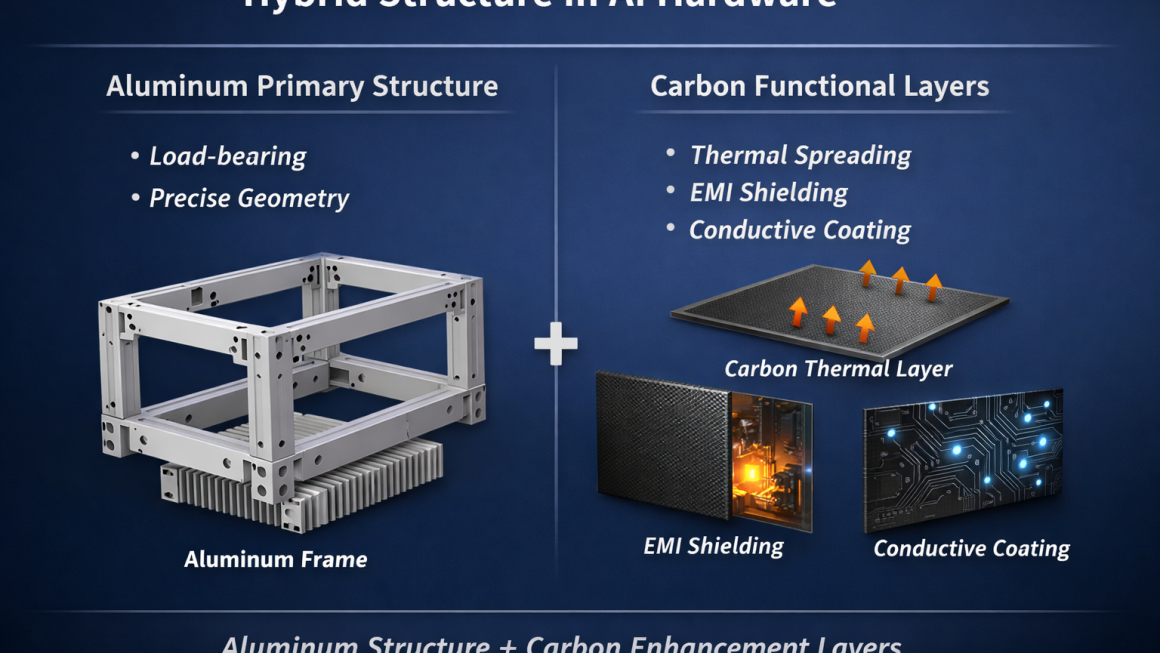

4️⃣ Typical Hybrid Scenarios

In practice, hybrid designs are increasingly explored. These remain conceptual or experimental, not standard production solutions:

- Aluminum frame + carbon-based coating: Localized conductivity or thermal enhancement on an aluminum frame.

- Aluminum heat sink + carbon thermal layer: Thin carbon layer improves heat spreading on an aluminum heat sink.

- Aluminum enclosure + conductive carbon fillers: Enhances EMI shielding inside aluminum chassis.

Careful wording: these are engineering explorations, not mass-production-ready solutions.

5️⃣ A Practical Rule for Engineers

A simple engineering rule can guide material selection early in the design process:

- If the function defines the shape → Aluminum first

- Any feature affecting dimensions, load-bearing, or assembly should default to aluminum.

- If the function enhances performance → Carbon selectively

- Electrical conductivity, thermal management, EMI shielding, or localized weight reduction can leverage carbon materials selectively.

This formula is straightforward yet powerful, giving engineers a rational approach in aluminum vs carbon materials engineering decisions without being swayed by marketing hype.

6️⃣ What We Intentionally Do NOT Promise

Clear boundaries and expectations are essential:

- No claims of full carbon structural replacement

- Carbon materials are not guaranteed to replace aluminum primary structures.

- No blanket scalability statements

- Performance and manufacturability of carbon vary by batch and process, and cannot be generalized.

- No performance guarantees without system-level validation

- Functional enhancement must be verified at the system level, not just with material-level testing.

This honesty builds trust, helping engineers navigate aluminum frame carbon enhancement and AI server mechanical design materials with confidence.

In AI hardware, aluminum is the structural baseline, carbon materials are the functional enhancers. Understanding the boundary between them helps engineers make rational material choices and avoid unexpected risks early in the design cycle.

Core takeaway: Shape is defined by aluminum, performance is selectively enhanced by carbon.