Functional Add-Ons for Advanced Aluminum Systems

Enhancing thermal, electrical, and durability performance beyond conventional aluminum.

Why Functional Enhancement Matters

As AI infrastructure and high-power electronics continue to evolve, conventional aluminum alone often reaches its performance limits.

Functional add-ons based on graphene and carbon nanotube (CNT) technologies enable targeted performance enhancement without redesigning the entire structure.

These solutions are designed to be compatible with existing aluminum components and manufacturing processes.

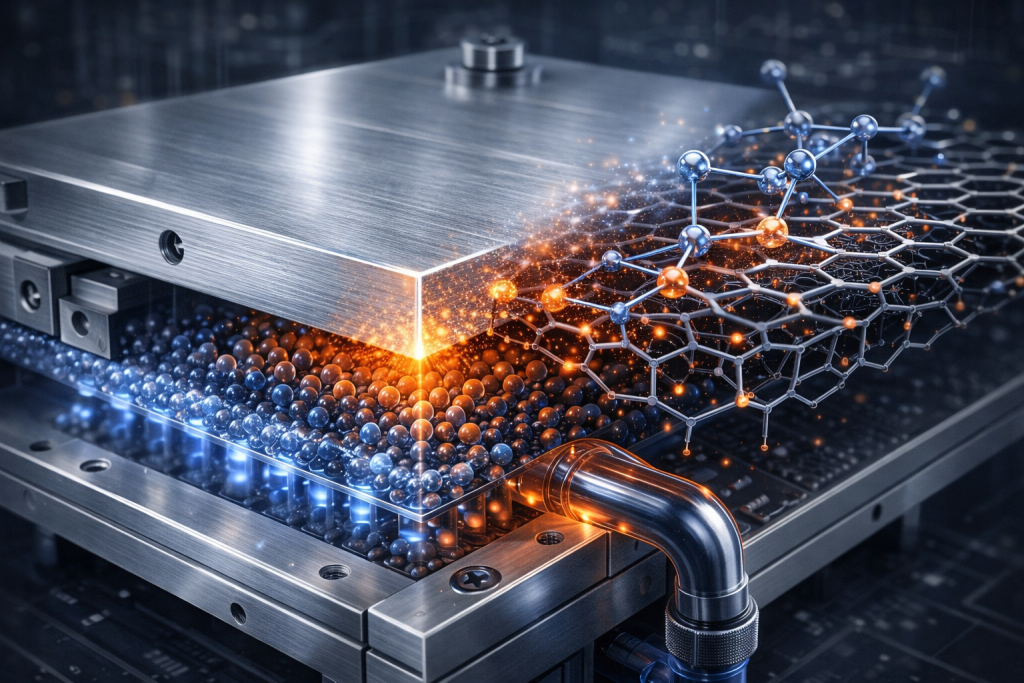

Graphene-Enhanced Thermal Coatings

Thin-layer graphene-based coatings applied to aluminum surfaces for selective or experimental performance enhancement, targeting improved heat transfer and surface thermal behavior.

Key Benefits

Enhanced in-plane heat spreading under validated conditions

Improved thermal interface efficiency for specific thermal designs

Minimal impact on component weight and geometry when properly implemented

Typical Applications

Heat sinks (evaluation and pilot use)

Cold plates for targeted thermal studies

High heat-flux aluminum components with customized validation

CNT-Based Conductive Layers

Carbon nanotube-based conductive layers applied to aluminum substrates for selective or application-specific use, targeting enhanced electrical conductivity or multifunctional performance.

Key Benefits

Improved electrical conductivity under defined and validated conditions

Enhanced multifunctional performance for targeted applications

Suitable for EMI-related or advanced electronic applications on a project-specific basis

Typical Applications

Structural conductive components with customized validation

Hybrid electrical-thermal aluminum parts for specialized designs

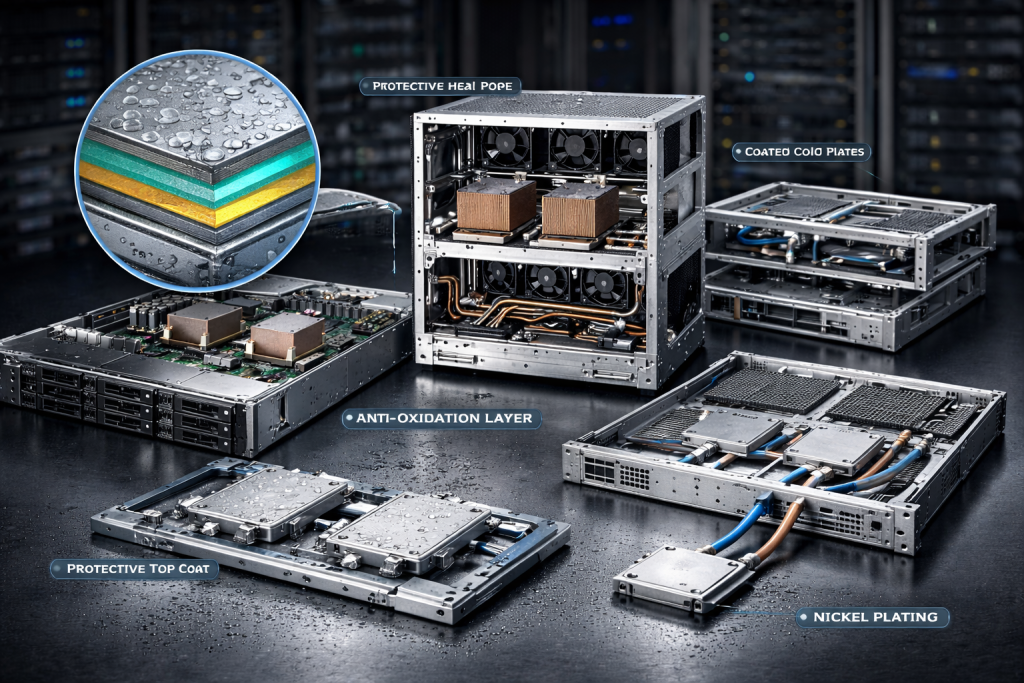

Anti-Corrosion & Anti-Oxidation Protection

Advanced surface treatments and protective coatings applied to aluminum components to enhance durability and service life in demanding operating environments.

For harsh or long-term exposure conditions, graphene-enhanced protective coatings can be evaluated as an optional solution.

Key Benefits

Improved resistance to oxidation and corrosion under industrial operating conditions

Enhanced durability in humid or aggressive environments

Compatibility with thermal and functional coatings for integrated surface solutions

Typical Applications

Data center environments

Long-term industrial installations

Export-oriented aluminum systems

Energy storage enclosures and outdoor systems

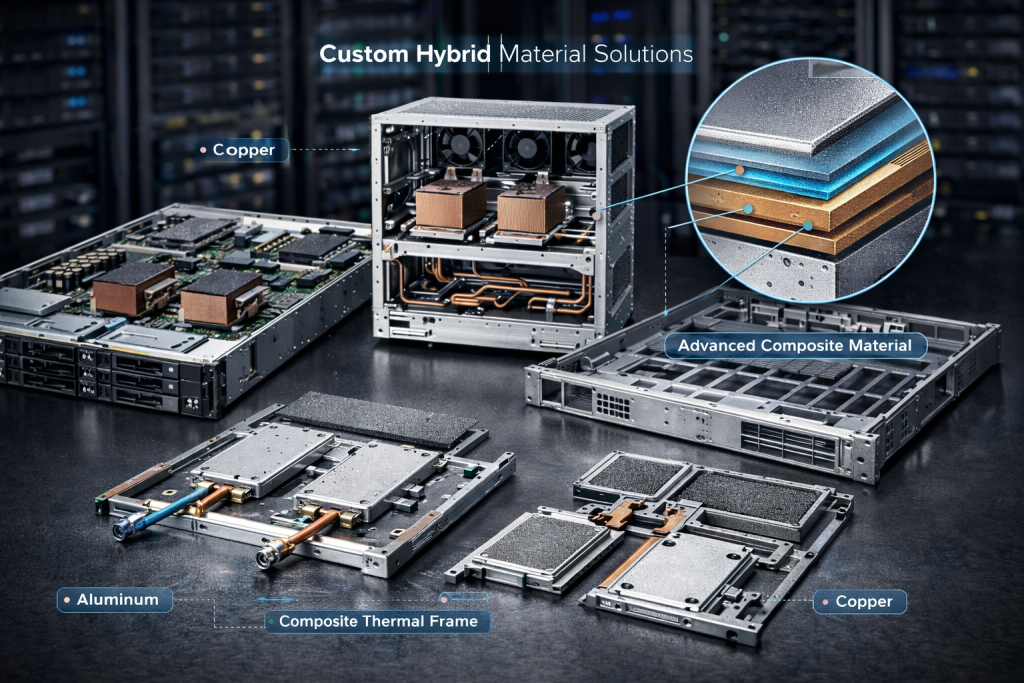

Custom Hybrid Material Solutions

We support the development of custom hybrid material solutions by combining aluminum with graphene, CNTs, or other functional materials for application-specific and system-level performance requirements.

Capabilities

Material selection and application-oriented evaluation

Surface functionalization concepts and feasibility assessment

Prototype support and early-stage validation

Production pathway planning based on validated project requirements

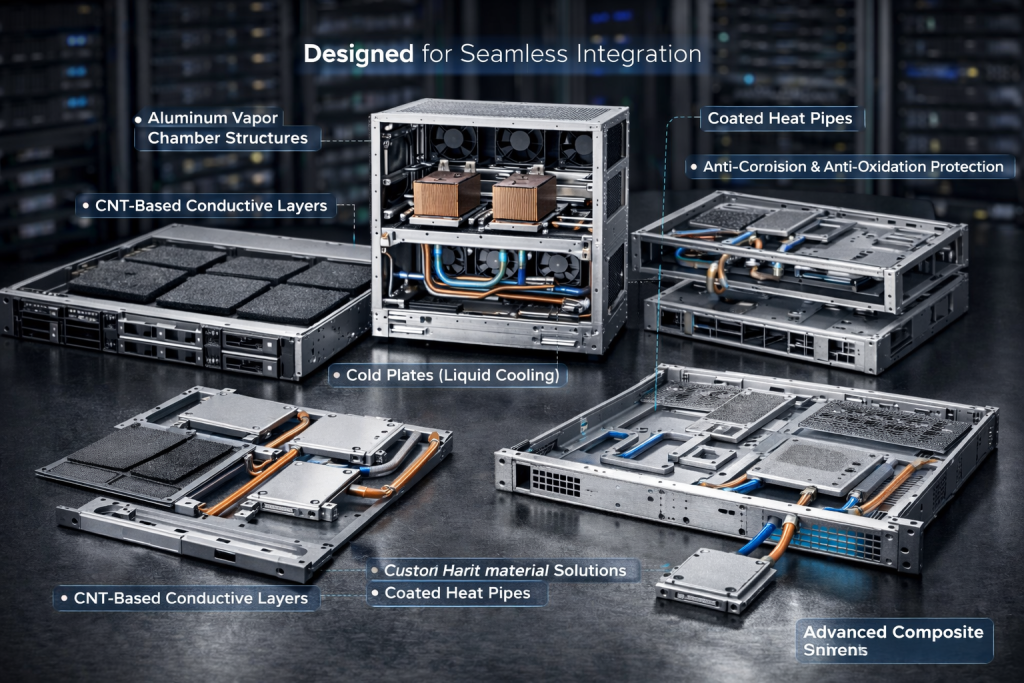

Designed for Integration-Oriented Engineering

Our functional add-ons are designed with integration compatibility in mind, supporting aluminum-based systems such as:

Aluminum extrusions

CNC-machined aluminum components

Thermal management structures

AI data center–related aluminum assemblies

The focus is performance enhancement while minimizing disruption to existing manufacturing and supply chains, subject to project-specific validation.

Target Application Scenarios

AI & HPC–related thermal management applications

High-power electronic components and assemblies

Advanced cooling solutions at component or module level

Next-generation aluminum-based infrastructure concepts and pilot projects