In AI hardware development, aluminum is widely used for frames, enclosures, heat-related components, and structural interfaces.

Yet one of the most underestimated decisions in early design stages is how the aluminum part should be made.

Machining and extrusion are often treated as interchangeable manufacturing options. In reality, they represent two very different engineering philosophies, each with its own cost structure, tolerance behavior, scalability limits, and design constraints.

Choosing the wrong process rarely causes immediate failure—but it almost always increases cost, delays iteration, or limits future scalability.

Understanding the Two Processes at a Fundamental Level

What Extrusion Really Means

Aluminum extrusion is a geometry-driven process.

A heated aluminum billet is pushed through a die, producing a continuous profile with a constant cross-section.

Key characteristics of extrusion:

- Cross-section remains uniform along length

- Excellent material utilization

- High repeatability at scale

- Strong dependency on die design and material flow

Extrusion works best when:

- Geometry is consistent

- Length is variable

- Production volume justifies tooling

What Machining Actually Optimizes For

Machining is a feature-driven process.

Material is removed from solid stock to create specific shapes, holes, interfaces, and tolerances.

Key characteristics of machining:

- Geometry freedom

- Localized precision

- Rapid design iteration

- Higher material waste and unit cost

Machining works best when:

- Features are complex or non-uniform

- Volumes are low to medium

- Tight local tolerances are required

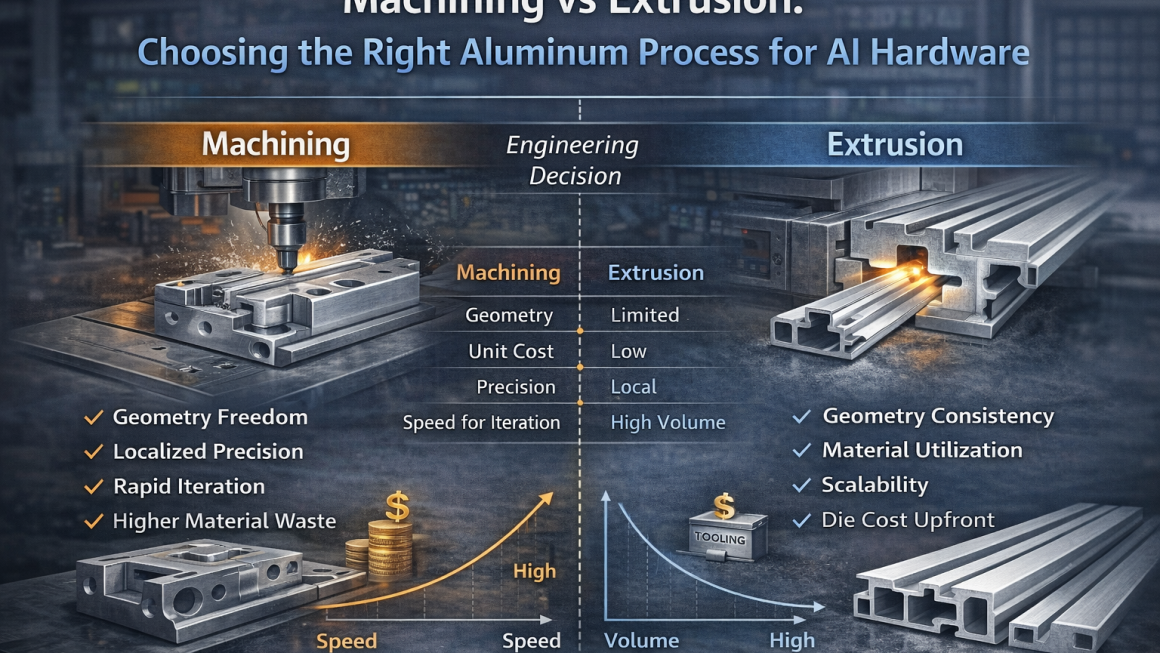

The Core Engineering Trade-Off

At a system level, the choice between machining and extrusion is not about accuracy versus cost—it is about where precision is truly needed.

| Dimension | Extrusion | Machining |

|---|---|---|

| Geometry freedom | Limited | High |

| Unit cost (volume) | Low | High |

| Tooling cost | Medium | Low |

| Tolerance consistency | Good (global) | Excellent (local) |

| Scalability | Excellent | Limited |

| Design iteration speed | Slow | Fast |

The mistake many teams make is applying machining-level precision to parts that should be extrusion-optimized, or forcing extrusion into geometries that fundamentally require machining.

Typical Use Cases in AI Hardware

Where Extrusion Excels

In AI hardware systems, extrusion is commonly used for:

- Rack frames and rails

- Structural beams and supports

- Modular enclosure profiles

- Cable management channels

These components benefit from:

- Long lengths

- Repetitive geometry

- Structural continuity

Extrusion also offers predictable mechanical behavior, which is essential for load-bearing frames and large-scale deployments.

Where Machining Is the Better Choice

Machining is more suitable for:

- Mounting interfaces

- Precision alignment features

- Heat sink bases with flatness requirements

- Custom brackets or adapters

In these cases, geometry complexity and tolerance precision outweigh material efficiency.

The Hidden Cost Factors Engineers Often Miss

Tooling vs Unit Cost Illusion

Extrusion tooling appears expensive at first glance.

However, once volume increases, the per-unit cost drops dramatically.

Machining, by contrast:

- Has low initial setup cost

- But scales linearly—or worse—with volume

For AI hardware expected to scale, early reliance on machining often creates a painful transition later.

Tolerance Accumulation Risk

Extruded profiles maintain excellent cross-sectional consistency, but:

- Length tolerance

- Cut accuracy

- Post-processing steps

must be considered at the system level.

Machining offers tighter local tolerances, but stacking multiple machined parts increases cumulative error if assembly logic is not carefully designed.

Hybrid Design: The Most Common (and Most Practical) Reality

In real AI hardware projects, the best solution is rarely “extrusion only” or “machining only”.

A common and effective approach is:

- Extruded aluminum profiles for primary structure

- Machined features applied selectively where needed

Examples include:

- Machined mounting holes on extruded frames

- Post-machined surfaces for flatness or alignment

- Extruded profiles combined with machined end plates

This hybrid approach balances:

- Cost

- Precision

- Scalability

without over-engineering any single component.

Design for Manufacturing Starts Earlier Than Most Teams Think

Many extrusion failures are not manufacturing problems—they are design expectation problems.

Common mistakes include:

- Non-uniform wall thickness

- Excessively sharp internal corners

- Complex internal cavities

- Assuming extrusion behaves like machining

Designing with extrusion in mind from the beginning:

- Reduces die complexity

- Improves yield

- Stabilizes quality across batches

Where Advanced Materials Enter the Discussion (Carefully)

In some AI hardware projects, carbon-based materials such as graphene or CNT-enhanced components are explored to improve thermal or electrical performance.

It is important to recognize that:

- These materials do not replace extrusion or machining processes

- They often introduce additional processing steps

- Integration complexity increases significantly

In practice, they are best considered as functional layers or localized enhancements, not manufacturing substitutes.

A Practical Decision Framework for Engineers

A simple rule of thumb:

- If shape defines function → consider extrusion first

- If features define function → machining is likely necessary

- If scale matters → extrusion becomes increasingly valuable

- If iteration speed matters → machining offers flexibility

The correct choice is rarely emotional or trend-driven—it is context-driven.

Machining and extrusion are not competing processes; they are complementary tools in aluminum engineering.

For AI hardware designers, the goal is not maximum precision or minimum cost in isolation, but a balanced system that scales reliably.

Understanding the strengths and limits of each process allows engineers to make informed decisions early—when changes are still affordable.

In AI infrastructure, manufacturing logic is just as important as material selection.