When discussing aluminum structures in AI systems, cost is often reduced to a simple equation: material price per kilogram multiplied by total weight.

In practice, this approach misses most of the real cost drivers.

For AI hardware—where reliability, scalability, and precision matter—the true cost of aluminum structures is shaped far more by design decisions, manufacturing logic, and system integration than by raw material price.

Understanding these hidden cost drivers allows engineers and decision-makers to avoid unnecessary expense without compromising performance.

Material Cost Is the Smallest Piece of the Puzzle

Aluminum itself is rarely the dominant cost factor in AI hardware structures.

While alloy selection does influence price, its impact is often overshadowed by:

- Processing complexity

- Assembly labor

- Quality control requirements

- Design inefficiencies

Focusing solely on material cost often leads to decisions that increase total system cost downstream.

Cost Driver #1: Over-Engineered Geometry

One of the most common sources of hidden cost is geometry that exceeds functional requirements.

Examples include:

- Excessively thick walls “for safety”

- Complex cross-sections with no structural benefit

- Decorative features that complicate extrusion or machining

These choices:

- Increase material usage

- Raise extrusion die cost

- Reduce yield

- Increase machining time

In AI systems, structural loads are often predictable. Designing beyond those requirements adds cost without adding value.

Cost Driver #2: Manufacturing Process Mismatch

Choosing the wrong manufacturing process early can lock in long-term cost penalties.

Common mismatches include:

- Machining parts that should be extruded

- Extruding profiles that require extensive post-machining

- Designing without considering tooling constraints

For example:

- Machining offers flexibility, but scales poorly with volume

- Extrusion offers scalability, but requires geometry discipline

When process selection does not align with expected production scale, costs escalate rapidly as systems move from prototype to deployment.

Cost Driver #3: Tolerance That Exceeds Functional Needs

Tight tolerances are expensive—not because they are difficult to specify, but because they:

- Increase rejection rates

- Slow down manufacturing

- Complicate assembly

In aluminum structures for AI systems, tolerance should be treated as a system parameter, not an isolated specification.

Over-tight tolerances often appear in:

- Mounting interfaces

- Structural joints

- Alignment features that do not directly affect performance

Specifying tolerance based on habit rather than function quietly increases cost across every production batch.

Cost Driver #4: Assembly Complexity and Labor

Assembly is one of the least visible—and most underestimated—cost drivers.

Factors that increase assembly cost include:

- High part count

- Non-modular structures

- Difficult access to fasteners

- Requirement for skilled manual alignment

Aluminum structures that are easy to manufacture but difficult to assemble often cost more overall than slightly more expensive profiles designed with assembly logic in mind.

For AI systems deployed at scale, assembly efficiency directly affects time-to-market and operational cost.

Cost Driver #5: Surface Treatment Decisions

Surface treatment is often treated as a cosmetic afterthought.

In reality, it significantly impacts:

- Corrosion resistance

- Electrical grounding behavior

- Thermal interface quality

- Long-term appearance

Common cost traps include:

- Over-specifying surface finishes

- Selecting treatments incompatible with assembly sequence

- Ignoring the impact on rework and repair

The most cost-effective surface treatment is the one that satisfies functional requirements—no more, no less.

Cost Driver #6: Late Design Changes

Late-stage design changes are among the most expensive events in aluminum structure development.

They often trigger:

- New extrusion dies

- Revised machining programs

- Requalification testing

- Inventory obsolescence

In AI hardware projects, late changes frequently result from:

- Incomplete system-level thinking

- Poor communication between mechanical and thermal teams

- Underestimating future scalability requirements

Designing with forward compatibility in mind reduces the likelihood of costly redesign cycles.

Cost Driver #7: Scaling Assumptions That Don’t Hold

A structure that is cost-effective at prototype scale may become prohibitively expensive at volume.

Typical scaling pitfalls include:

- Designs that rely heavily on manual machining

- Custom components with limited supplier base

- Assembly processes that cannot be automated

Aluminum structures intended for AI infrastructure must be evaluated not just for initial feasibility, but for repeatability and supply chain resilience.

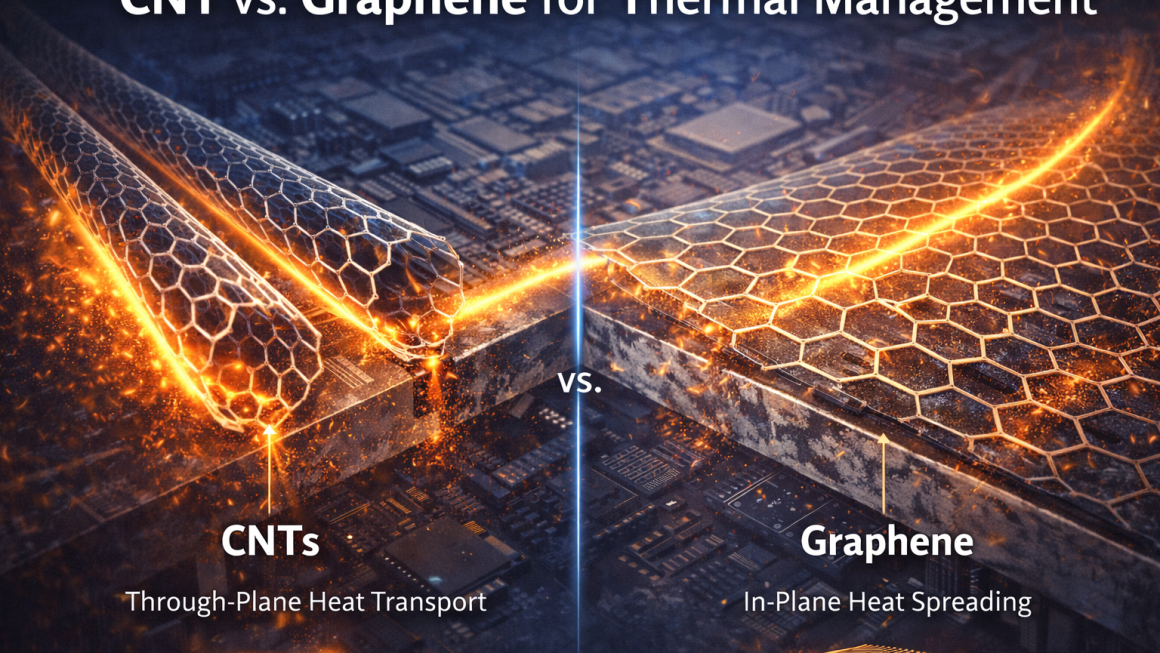

The Role of Advanced Materials—Without Cost Illusions

Carbon-based materials such as graphene or CNT-enhanced components are sometimes introduced with the expectation of cost reduction through performance gains.

In practice:

- Material cost is often higher

- Processing complexity increases

- Integration adds risk

These materials may deliver localized functional benefits, but they rarely reduce total system cost unless applied selectively and with clear performance justification.

They should be viewed as engineering tools, not cost shortcuts.

A System-Level Cost Mindset

The most effective cost optimization strategies in aluminum structures are not aggressive—they are disciplined.

They involve:

- Matching geometry to load paths

- Selecting manufacturing processes early

- Designing for assembly, not just fabrication

- Applying tolerance intentionally

- Thinking beyond the first production run

In AI systems, where infrastructure reliability is critical, the cheapest structure is often the one that avoids future problems.

Practical Takeaways for Engineers

- Material price is rarely the dominant cost driver

- Overdesign quietly increases cost at every stage

- Process selection determines scalability

- Assembly logic matters as much as structure

- Cost control starts at the design table

Hidden cost drivers in aluminum structures rarely appear on material quotes—but they dominate total system cost over time.

For AI systems, where deployment scale and reliability matter, understanding these drivers enables smarter engineering decisions and more predictable outcomes.

Cost optimization is not about cutting corners.

It is about designing with clarity, discipline, and system awareness from the very beginning.