Aluminum is widely used in AI hardware structures because it offers a rare balance of lightweight, strength, and thermal performance.

However, when aluminum is placed in real AI environments—high power density, continuous operation, and strict electrical requirements—engineers face a recurring dilemma:

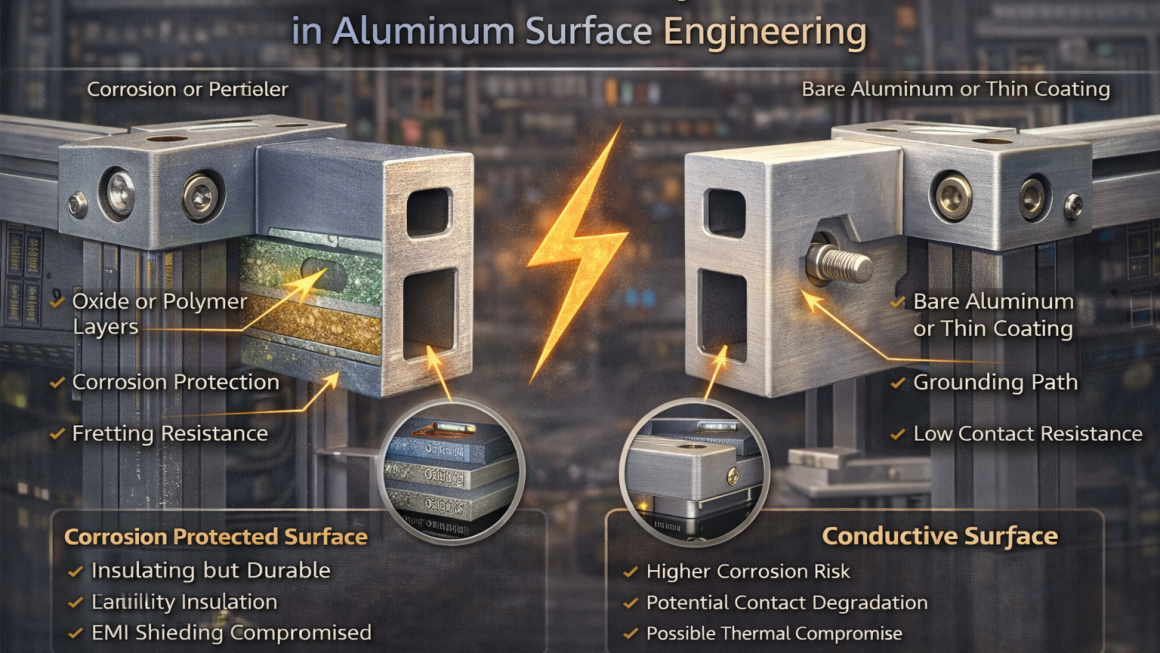

Should aluminum surfaces prioritize corrosion protection or electrical conductivity?

In many cases, improving one comes at the expense of the other. This article explores the engineering trade-offs between corrosion resistance and electrical conductivity in aluminum surface engineering, and how these choices affect long-term system performance.

1. Why This Trade-Off Exists

1.1 Aluminum’s Natural Oxide Layer

Aluminum forms a thin oxide layer naturally when exposed to air. This layer:

- Protects against corrosion

- Is electrically insulating

- Has limited thermal conductivity

While this natural oxide is thin, engineered surface treatments often amplify its effects, making trade-offs unavoidable.

2. Corrosion Protection: What Engineers Gain

2.1 Why Corrosion Still Matters in AI Systems

Even in climate-controlled data centers, aluminum surfaces face:

- Humidity fluctuations

- Cleaning agents and maintenance chemicals

- Long-term exposure to airborne contaminants

Corrosion may not cause immediate failure, but it can lead to:

- Surface pitting

- Increased contact resistance

- Reduced mechanical integrity over time

2.2 Common Corrosion-Focused Treatments

- Anodizing (standard or hard)

- Conversion coatings

- Polymer-based protective coatings

These treatments extend structural life but often reduce surface conductivity.

3. Electrical Conductivity: Why It Cannot Be Ignored

3.1 Grounding and EMI Control

In AI racks, aluminum frames often serve as:

- Grounding paths

- EMI shielding structures

- Mechanical references for signal stability

Poor electrical continuity can cause:

- Ground loops

- Increased electromagnetic noise

- Inconsistent system behavior

3.2 Contact Interfaces Are Critical

Conductivity matters most at:

- Frame-to-frame joints

- Rack mounting points

- Shielding interfaces

- Cable management structures

At these locations, insulating surface layers can undermine electrical design intent.

4. How Surface Treatments Shift the Balance

4.1 Anodizing: Protection at a Cost

Advantages:

- Excellent corrosion resistance

- Improved wear performance

Trade-Offs:

- Electrically insulating

- May require selective masking or post-processing

- Can increase contact resistance at joints

Anodizing works best when electrical continuity is managed intentionally, not assumed.

4.2 Bare or Lightly Treated Aluminum

Advantages:

- Excellent electrical conductivity

- Low contact resistance

Trade-Offs:

- Higher corrosion risk

- Surface degradation over time

- Requires controlled environment

This approach may work in short lifecycle or tightly controlled installations, but risks increase with time.

4.3 Hybrid Approaches

Many AI systems use mixed strategies:

- Conductive contact points left untreated or lightly treated

- Structural surfaces protected with anodizing

- Grounding zones mechanically broken through coatings

This method demands clear engineering documentation to avoid assembly errors.

5. Mechanical and Thermal Side Effects

5.1 Mechanical Stability

- Insulating coatings reduce fretting and wear

- Bare aluminum can develop micro-movement damage at joints

5.2 Thermal Interfaces

- Thick coatings increase thermal resistance

- Polished or lightly treated surfaces improve thermal contact

- Trade-offs affect long-term heat dissipation stability

Thermal, electrical, and mechanical behaviors are tightly coupled.

6. Common Engineering Misconceptions

❌ “Anodized aluminum cannot be grounded”

→ It can, but grounding must be designed, not assumed.

❌ “Bare aluminum is always better electrically”

→ Initially yes, but corrosion can degrade conductivity over time.

❌ “One surface treatment fits the entire frame”

→ In AI systems, functional zoning is essential.

7. Practical Design Guidelines

For AI hardware aluminum structures:

- Define electrical grounding zones early in design

- Use selective surface treatment, not blanket coatings

- Keep thermal contact surfaces smooth and minimally treated

- Document coating thickness and contact requirements

- Align mechanical, electrical, and thermal teams on surface strategy

Good surface engineering is a system-level decision, not a finishing step.

In aluminum surface engineering for AI environments, the choice between corrosion resistance and electrical conductivity is rarely binary.

The real challenge is managing the trade-off intelligently:

- Protect where durability matters

- Conduct where electrical performance is critical

- Design interfaces that acknowledge both

As AI systems grow in power density and operational lifespan, surface engineering decisions increasingly shape long-term reliability.