Opening

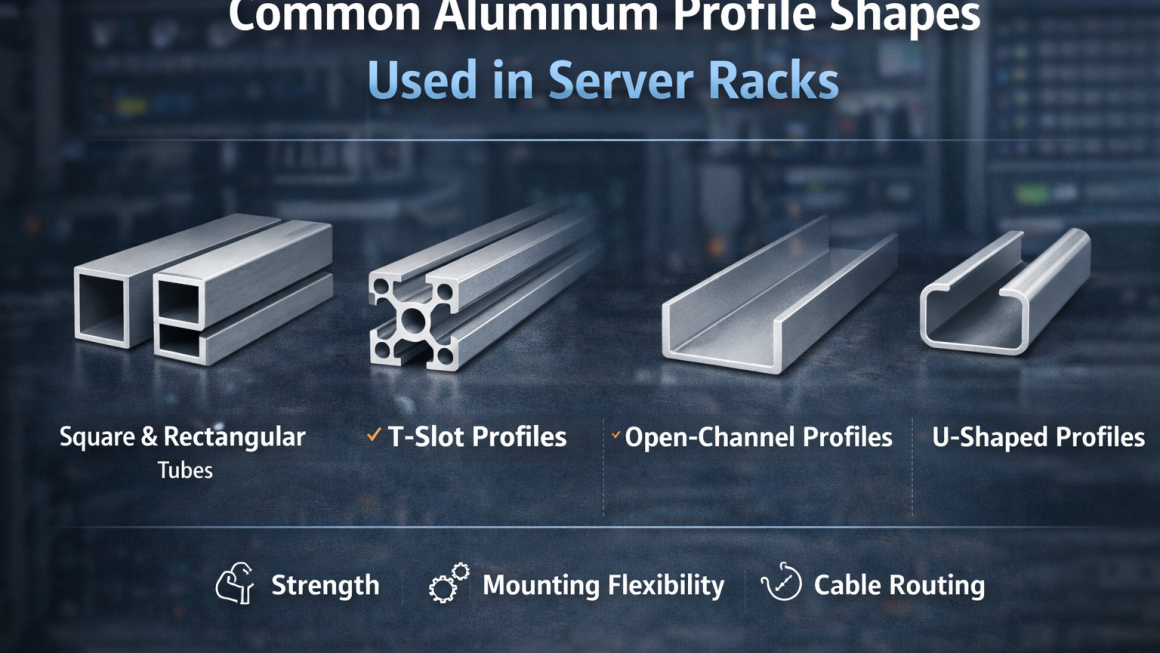

Server rack performance is influenced not only by electronics, but by the geometry of its supporting aluminum profiles.

Profile shape directly affects load distribution, airflow, and assembly efficiency.

Core Engineering Logic

Common aluminum profile shapes include:

- Square and rectangular hollow sections

- T-slot modular profiles

- Open-channel and U-shaped profiles

Each shape introduces different stiffness characteristics and mounting flexibility.

For example:

- Hollow profiles improve strength-to-weight ratio

- T-slot profiles enable rapid assembly and reconfiguration

- Open profiles simplify cable routing but reduce torsional rigidity

Practical Engineering Considerations

- Match profile geometry to load direction

- Avoid unnecessary wall thickness

- Consider airflow interaction with profile cross-sections

- Balance rigidity and accessibility

Advanced Material Perspective

Some designs investigate carbon-enhanced inserts for localized stiffness improvements.

These approaches remain design explorations rather than standardized solutions.

Profile geometry is a design decision, not a cosmetic one.

Understanding shape-function relationships improves rack reliability and serviceability.