As AI hardware systems continue to increase in power density and complexity, material discussions often shift toward advanced carbon materials—graphene, carbon coatings, carbon-filled composites, and conductive carbon layers.

In many cases, these materials are introduced with ambitious claims of replacing traditional metals.

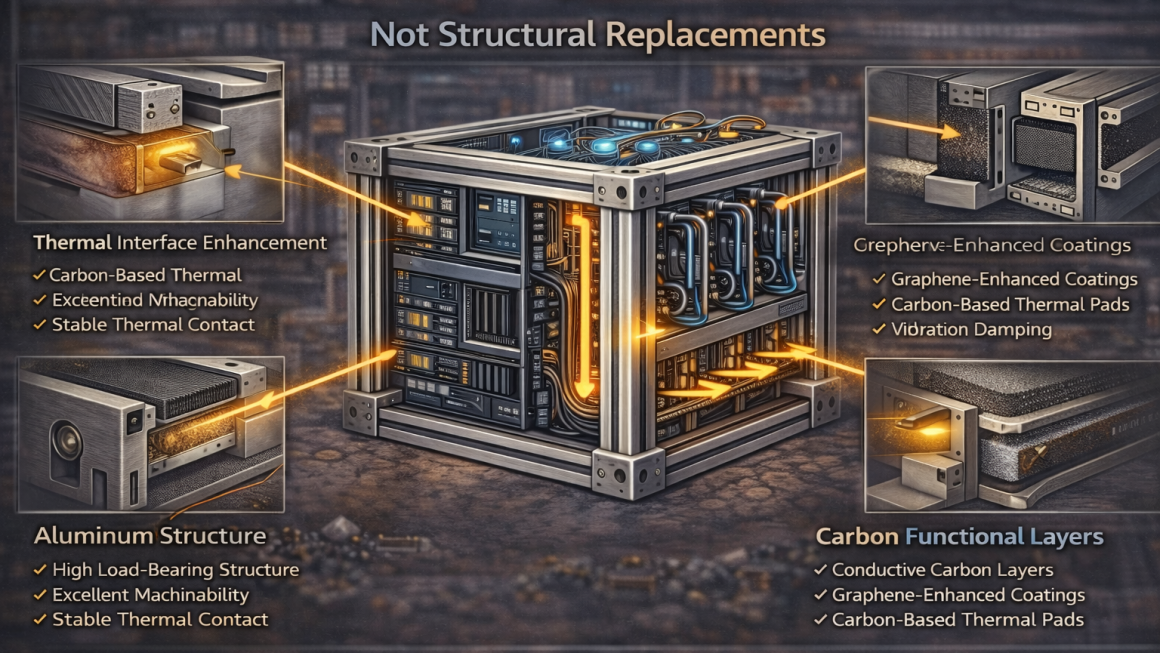

However, in real-world AI hardware engineering, carbon materials rarely serve as structural replacements for aluminum.

Instead, their true value lies elsewhere.

This article clarifies how carbon materials actually function in AI hardware systems—as performance enhancers, not load-bearing substitutes—and why aluminum remains the backbone of AI structures.

1. Why Aluminum Remains Structurally Dominant

Before discussing carbon materials, it’s important to understand why aluminum continues to dominate AI hardware structures.

Aluminum provides:

- Predictable mechanical strength

- Excellent machinability and extrusion flexibility

- Stable tolerances at scale

- High thermal conductivity relative to weight

- Proven reliability over long lifecycles

For racks, frames, rails, and structural members, aluminum delivers system-level reliability that carbon materials cannot yet replace economically or practically.

Carbon materials excel elsewhere—but not as primary structural frames.

2. What Carbon Materials Actually Do Well

Carbon materials bring functional advantages that complement aluminum rather than compete with it.

2.1 Thermal Interface Enhancement

Carbon-based materials can improve:

- Heat spreading at localized hotspots

- Thermal interface performance between components

- Reduction of thermal contact resistance

Examples include:

- Graphene-enhanced coatings

- Carbon-based thermal pads

- Carbon-filled interface layers

These materials are used where heat transfer efficiency matters most, not where structural rigidity is required.

2.2 Electrical Conductivity and EMI Control

Carbon materials offer:

- Stable surface conductivity

- EMI attenuation and shielding enhancement

- Controlled grounding paths

Carbon coatings or films are often applied:

- At electrical contact points

- On aluminum surfaces requiring conductivity without corrosion risk

- In hybrid grounding strategies

They function as electrical performance layers, not mechanical supports.

2.3 Vibration Damping and Fatigue Mitigation

One underappreciated benefit of carbon materials is energy dissipation.

When applied correctly, carbon layers can:

- Reduce micro-vibration at interfaces

- Limit fretting wear between aluminum joints

- Improve long-term mechanical stability

This is particularly valuable in:

- Fan-heavy AI servers

- Liquid-cooled systems with pump-induced vibration

3. Where Carbon Materials Should Not Be Used

Understanding limits is as important as understanding strengths.

Carbon materials generally:

- Lack ductility compared to aluminum

- Are brittle under mechanical shock

- Have inconsistent large-scale manufacturing tolerances

- Are cost-sensitive at volume

As a result, they are unsuitable for:

- Primary load-bearing frames

- Long-span structural members

- Precision-aligned mechanical assemblies

Replacing aluminum frames with carbon materials often introduces new risks without meaningful system benefits.

4. Hybrid Design: Aluminum + Carbon at the Interface Level

The most effective AI hardware designs use hybrid material strategies.

4.1 Aluminum as the Structure

- Frames

- Rails

- Mounting brackets

- Heat sink bodies

4.2 Carbon as the Functional Layer

- Thermal enhancement coatings

- Conductive surface layers

- EMI suppression films

- Interface damping elements

This division of roles preserves structural predictability while unlocking advanced functional performance.

5. Carbon Materials and Manufacturability Reality

In AI infrastructure, manufacturability matters as much as performance.

Carbon materials often introduce:

- Batch-to-batch variability

- Complex surface preparation requirements

- Higher inspection and QA costs

By contrast, aluminum:

- Scales efficiently

- Maintains tight tolerances

- Integrates seamlessly with CNC and extrusion processes

Carbon materials are most successful when they:

- Enhance existing aluminum processes

- Do not disrupt supply chain stability

- Remain modular and replaceable

6. Misconceptions to Avoid

❌ “Graphene can replace aluminum frames”

→ In AI systems, this is rarely practical or necessary.

❌ “Carbon materials automatically improve everything”

→ Poor integration can worsen thermal, electrical, or mechanical performance.

❌ “Carbon = future, aluminum = legacy”

→ In reality, aluminum is evolving through material and surface engineering, not being displaced.

7. Practical Engineering Guidance

For AI hardware designers considering carbon materials:

- Start with clear functional objectives (thermal, electrical, damping)

- Apply carbon materials at interfaces, not structures

- Validate long-term stability, not just initial performance

- Avoid over-design driven by marketing narratives

- Treat carbon materials as engineering tools, not structural miracles

8. Looking Forward: Carbon Materials as Enablers

As AI systems push toward:

- Higher rack densities

- Tighter thermal margins

- Longer continuous operation

Carbon materials will increasingly serve as:

- Performance fine-tuning elements

- Reliability enhancers

- Interface optimizers

But aluminum will remain the structural foundation, providing the mechanical and thermal backbone upon which these enhancements are applied.

In AI hardware systems, carbon materials are not structural replacements for aluminum—and they don’t need to be.

Their real value lies in:

- Enhancing thermal paths

- Improving electrical behavior

- Reducing vibration and wear

- Extending system reliability

When used correctly, carbon materials and aluminum form a complementary system, not a competitive one.

The future of AI hardware is not about replacing aluminum—but about engineering smarter material combinations.