Engineering Considerations for Thermal, Structural, and Scalable Design

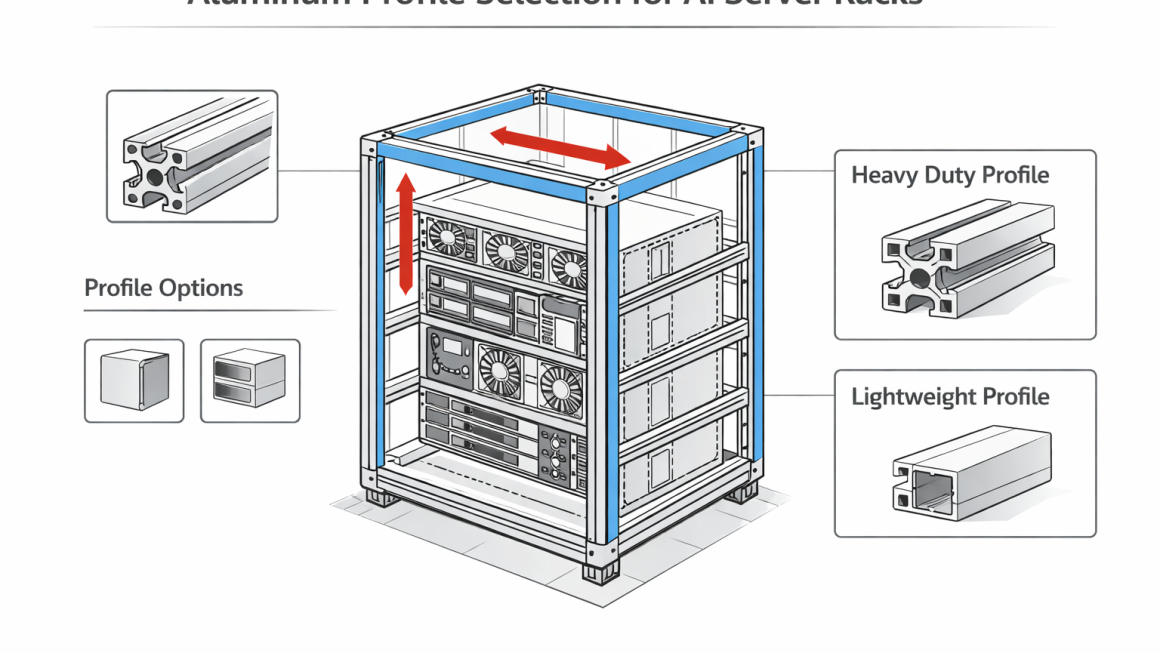

1. Why aluminum profiles remain a practical choice for AI server racks

AI server racks continue to increase in power density, weight, and integration complexity.

Despite ongoing discussions around advanced materials, aluminum profiles remain one of the most widely used structural solutions for rack systems.

This is not due to novelty, but due to a balance of factors that matter in real deployments:

- predictable mechanical behavior

- adequate thermal conductivity for structural heat spreading

- mature extrusion and machining processes

- stable supply chains at scale

In rack-level design, engineering reliability often outweighs material novelty.

2. Thermal considerations beyond nominal conductivity

Thermal performance in server racks is rarely limited by bulk material conductivity alone.

In practice, aluminum profiles contribute to thermal management mainly through:

- heat spreading along structural members

- interaction with airflow paths

- contact interfaces with mounted components

Profile geometry, wall thickness, and surface condition often have greater impact than alloy selection alone.

High thermal conductivity values on datasheets do not automatically translate into effective heat dissipation at the system level.

Interfaces, airflow, and manufacturability define real performance.

3. Structural requirements under high-density AI loads

Modern AI racks impose combined challenges:

- increasing static loads from dense compute modules

- long-term deformation risk

- vibration during operation and transportation

- tolerance accumulation across assembled profiles

Aluminum profiles are often selected not because they are the strongest material available,

but because their structural behavior is well understood and controllable within industrial manufacturing limits.

Design margins, not material extremes, usually determine reliability.

4. Manufacturability as an engineering constraint

A rack design that performs well in simulation but cannot be manufactured consistently is not a solution.

When selecting aluminum profiles, engineering teams must consider:

- extrusion feasibility and die limitations

- profile complexity versus yield rate

- machining tolerance repeatability

- assembly efficiency at scale

Manufacturability directly affects cost, lead time, and quality stability —

all of which are part of system performance.

5. When aluminum is sufficient — and when further development is required

In most production-ready AI server rack systems, aluminum profiles are sufficient to meet:

- structural requirements

- thermal spreading needs

- scalability expectations

Emerging materials such as graphene- or carbon nanotube–based solutions may offer interesting properties,

but they belong in controlled R&D and validation programs, not in assumptions for immediate production use.

In such cases, materials should support experimentation and verification —

not replace engineering decisions prematurely.

6. Engineering decisions come before material upgrades

Material selection should follow system understanding, not precede it.

For AI server racks, aluminum profiles continue to serve as a reliable engineering baseline —

one that allows designers to optimize structure, thermal behavior, and manufacturability in parallel.

New materials may play a role in future designs,

but only after their behavior is validated within real system constraints.

Engineering defines readiness. Materials support the process.