Practical engineering references for AI data center aluminum structures and thermal systems

We publish practical engineering guides focused on aluminum structures, thermal management, and material selection for AI data centers and high-performance computing infrastructure.

These guides are written for system designers, mechanical engineers, and sourcing teams seeking reliable, manufacturable, and scalable solutions.

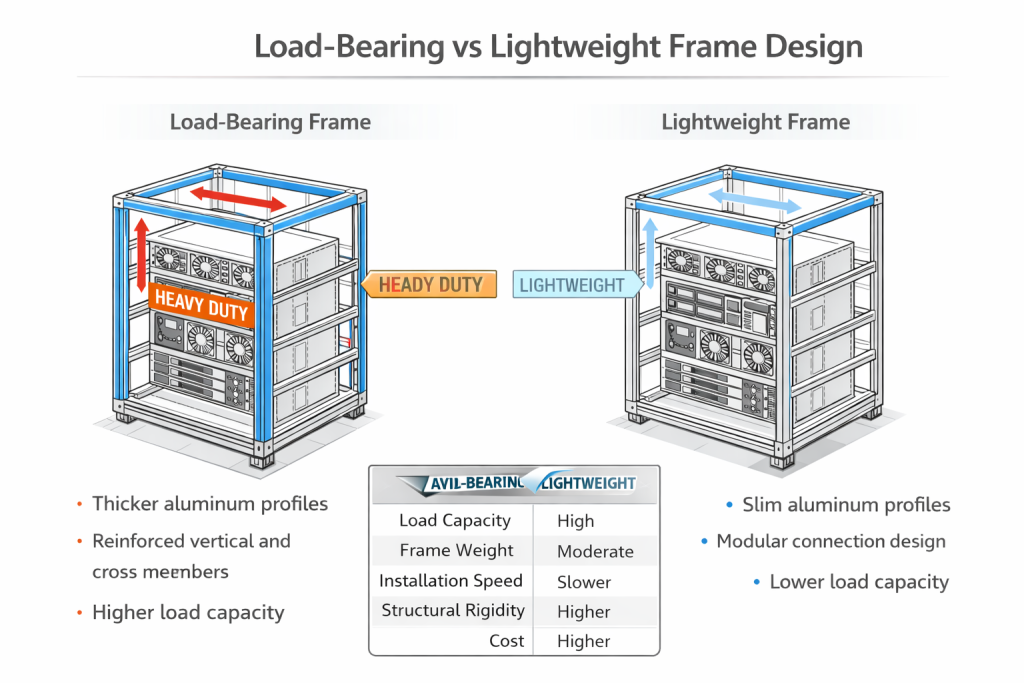

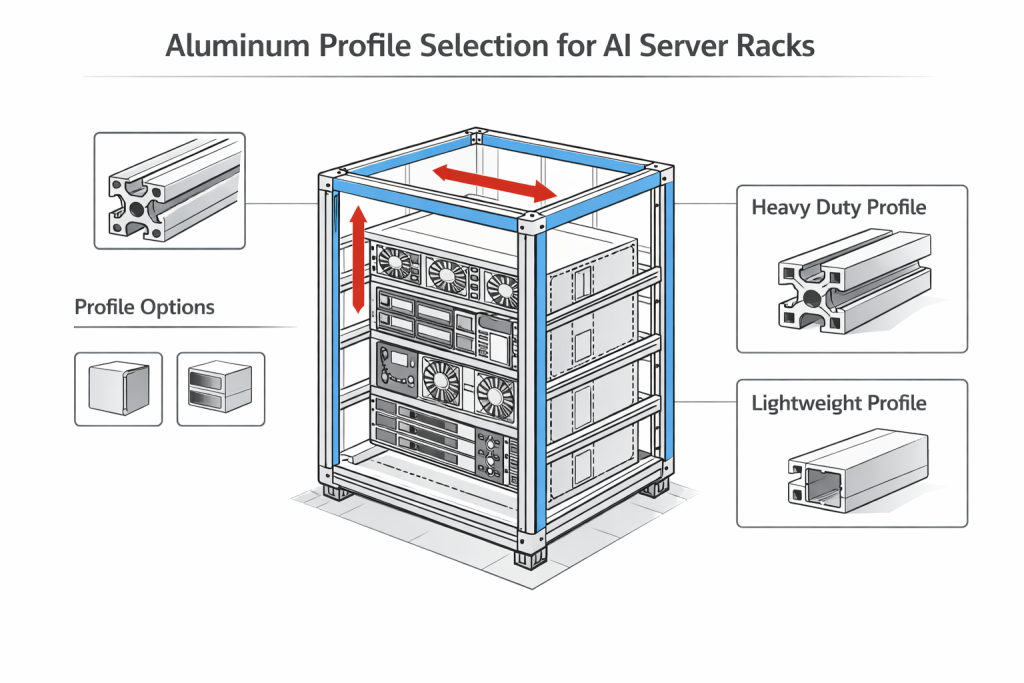

Structural Aluminum Design

Vibration, rigidity, and long-span considerations

How do I balance strength, weight, and manufacturability in aluminum rack systems?

Thermal Aluminum Engineering

Aluminum vs copper in AI cooling systems

Cold plate design fundamentals

Heat sink geometry: extrusion vs CNC vs folded fin

Thermal conductivity vs weight trade-offs

When is aluminum the better thermal solution, and how should it be designed?

Liquid Cooling Structures

Aluminum cold plate channel design

Structural integration of liquid cooling components

Flow uniformity and pressure drop basics

Corrosion considerations in liquid environments

How do structural aluminum parts interact with liquid cooling systems?

Materials & Surface Engineering

Aluminum alloy comparison (6xxx, 7xxx, custom alloys)

Surface roughness and thermal contact resistance

Anodizing vs coating for thermal and corrosion performance

Hybrid material approaches (aluminum + functional layers)

How do surface treatments affect real-world thermal and durability performance?

Advanced Materials Integration (Graphene / CNT)

When graphene or CNT layers make sense — and when they don’t

Electrical conductivity and EMI considerations

Thermal interface enhancement concepts

Manufacturability and cost boundaries

How can advanced materials enhance aluminum systems without breaking scalability?

Guide Format

Engineering background (no marketing language)

Design principles & constraints

Practical diagrams or abstractions

Common mistakes & design traps

Manufacturing and supply-chain considerations

We focus on what works in production, not laboratory-only results.