Why Mechanical Stability Matters in High-Density AI Infrastructure

As AI computing density continues to rise, attention is often focused on thermal management, power delivery, and signal integrity. However, an equally critical—yet frequently underestimated—factor is mechanical reliability.

In high-density AI racks, aluminum frames and structural components must withstand:

- Continuous vibration from high-speed fans and liquid cooling pumps

- Long-term cyclic stress and fatigue loading

- Thermal expansion and contraction during frequent power cycles

- Mechanical shock during transportation, installation, and maintenance

Failure to properly address these mechanical challenges can result in misalignment, microcracking, thermal interface degradation, and ultimately system instability.

This article explores how vibration, fatigue, and structural design affect the long-term stability of aluminum frames in AI hardware systems.

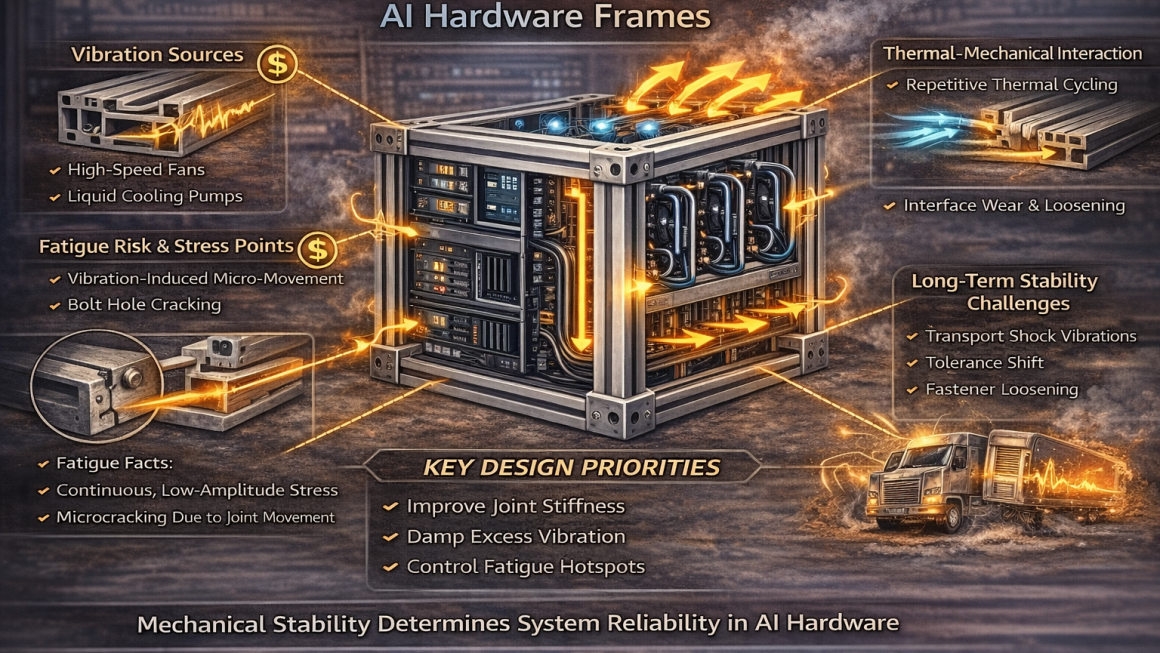

1. Sources of Vibration in AI Hardware Systems

AI servers are far from static environments. Common vibration sources include:

1.1 Cooling System-Induced Vibration

- High-RPM axial and centrifugal fans

- Liquid cooling pumps and flow-induced turbulence

- Resonance within airflow channels and plenums

These vibrations are often continuous and broadband, creating long-term fatigue risks.

1.2 Operational and Environmental Vibration

- Rack-level vibration from adjacent equipment

- Building vibration in large-scale data centers

- Seismic micro-vibrations in certain geographic regions

While each source may seem minor individually, their cumulative effect over years of operation is significant.

2. Fatigue Behavior of Aluminum Frames

2.1 Aluminum and Fatigue Characteristics

Aluminum alloys are widely used in AI hardware frames due to their:

- High strength-to-weight ratio

- Excellent machinability

- Good thermal conductivity

However, unlike steel, aluminum does not exhibit a true fatigue endurance limit. This means:

Even low-amplitude cyclic stress can eventually lead to fatigue failure if repeated enough times.

2.2 High-Risk Fatigue Zones in AI Frames

Typical fatigue-sensitive areas include:

- Bolt holes and fastener interfaces

- Sharp corners and insufficient fillet radii

- Thin-wall sections under bending loads

- Welded or bonded joints

Designing without accounting for these zones can shorten frame lifespan dramatically.

3. Structural Design Strategies for Vibration Resistance

3.1 Frame Geometry Optimization

Proper aluminum frame design can significantly reduce vibration-induced stress:

- Use closed-section profiles instead of open channels

- Increase moment of inertia without excessive weight

- Avoid long, unsupported spans

Well-designed geometry improves natural frequency separation, reducing resonance risk.

3.2 Joint and Fastener Design

Connections often determine overall stability:

- Preload-controlled fasteners to prevent micro-slip

- Use of threaded inserts in soft aluminum

- Avoid over-constraining assemblies that amplify stress

Poor joint design is a common cause of loosening, noise, and fatigue cracking.

4. Thermal–Mechanical Coupling: A Hidden Risk

4.1 Thermal Expansion Effects

AI hardware operates under frequent thermal cycling:

- Startup and shutdown cycles

- Load-dependent temperature fluctuations

- Localized hotspots near GPUs and power modules

Aluminum’s relatively high thermal expansion coefficient means:

- Repeated expansion and contraction increase fatigue stress

- Thermal mismatch with PCBs, heat sinks, and TIMs accelerates wear

4.2 Impact on Thermal Interfaces

Mechanical instability can degrade:

- TIM contact pressure

- Heat sink alignment

- Cold plate flatness

This leads to higher thermal resistance over time, even if cooling systems remain unchanged.

5. Long-Term Stability and Reliability Considerations

5.1 Structural Creep and Relaxation

Under constant load and elevated temperature:

- Fastener preload can relax

- Contact pressure gradually decreases

- Vibration amplitude increases over time

This is especially relevant in 24/7 AI training clusters.

5.2 Transport and Installation Stress

Many failures originate before systems are even powered on:

- Shock loading during shipping

- Improper rack mounting

- Uneven floor loading

Designing frames only for operational loads is insufficient—lifecycle loading must be considered.

6. Materials and Surface Engineering Approaches

6.1 Alloy Selection

Different aluminum alloys offer trade-offs:

- Higher strength alloys improve stiffness but may reduce corrosion resistance

- Softer alloys damp vibration better but may deform under load

Selection should be application-specific, not cost-driven.

6.2 Surface Treatments and Reinforcement

Surface engineering can enhance long-term stability:

- Hard anodizing to improve wear resistance

- Structural coatings to reduce fretting at interfaces

- Composite or carbon-based reinforcement layers for damping

Advanced materials approaches are increasingly explored in next-generation AI racks.

7. Designing for 5–10 Years of Continuous Operation

For hyperscale and edge AI deployments, frames must be designed not just to pass initial testing, but to:

- Maintain mechanical integrity over billions of vibration cycles

- Preserve thermal contact quality over years

- Support modular upgrades without structural degradation

This requires integrated thermal–mechanical design thinking, not isolated component optimization.

Mechanical Reliability Is a System-Level Issue

In high-density AI hardware, aluminum frames are more than structural supports—they are mechanical, thermal, and reliability-critical components.

By addressing vibration behavior, fatigue resistance, and long-term stability early in the design phase, system architects can:

- Reduce unexpected downtime

- Preserve thermal performance

- Extend equipment lifespan

As AI systems continue to scale in power and density, mechanical design will increasingly define system reliability.