As artificial intelligence (AI) systems evolve, so does the complexity of their hardware—particularly the thermal demands.

High-density AI systems, which house powerful processors, GPUs, and increasingly sophisticated cooling systems, generate heat in ways that traditional computing hardware never did. Aluminum, a primary structural material, plays a significant role in how heat moves through these systems.

In this article, we explore the thermal path design in aluminum structures and how their geometry and material properties directly influence heat flow in AI hardware systems.

1. What Is a Thermal Path?

In simple terms, a thermal path is the route heat takes from heat-generating components to heat sinks or the external environment.

In high-density AI racks, thermal paths are actively shaped by the materials and structures that make up the hardware.

Key components that form thermal paths include:

- Heat sources such as CPUs, GPUs, and memory chips

- Thermal interfaces like thermal pads or heat pipes

- Aluminum frames that transport heat across the system

- Airflow channels (either passive or forced convection)

Aluminum frames are integral to guiding, dissipating, and managing heat generated by high-performance AI hardware. But aluminum’s role is often underestimated when considering heat management in high-density systems.

2. Aluminum’s Thermal Conductivity: An Advantage and a Challenge

One of aluminum’s most valuable properties is its high thermal conductivity.

Aluminum conducts heat well, which helps spread heat evenly across the structure and prevents localized hotspots.

However, there are several important thermal design considerations when using aluminum in AI systems:

- Thermal bridging: Aluminum can act as a thermal bridge if not carefully designed. Heat can spread to non-targeted areas, potentially raising temperatures in sensitive spots.

- Heat distribution: While aluminum helps spread heat, its efficiency depends on geometry. A profile with sharp corners or thin sections may cause localized heat buildup, defeating the purpose of using aluminum’s conductive properties.

- Thermal expansion: As aluminum heats up, it expands, which can create mechanical stress in the system, affecting alignment and tolerances.

3. Geometry’s Role in Thermal Path Design

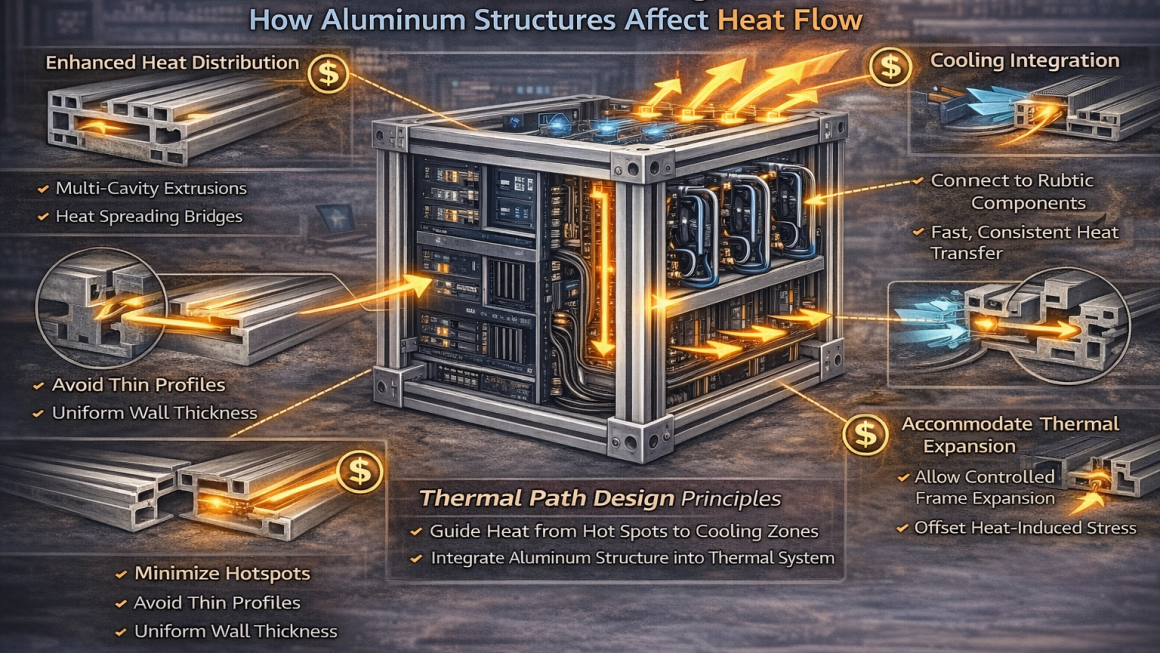

The design of aluminum profiles plays a crucial role in how heat travels through a system.

Profile Shape:

- Multi-cavity extrusions create profiles that improve stiffness but also distribute heat more effectively, especially when aligned with airflow paths.

- Thicker sections are generally better at conducting heat but come with a weight tradeoff.

- Open profiles (such as U-channels) help facilitate airflow while maintaining heat dissipation.

Design Considerations:

- Uniform thickness: Non-uniform thickness can lead to uneven heat distribution. A section with a thinner profile will not conduct heat as effectively, creating thermal bottlenecks.

- Airflow compatibility: Aluminum frames must be designed not just to support the weight of components, but also to allow air to flow freely around heat-generating parts. The geometry should incorporate spaces for air ducts and cooling components.

4. Aluminum Frames vs. Cooling Systems: Integration Challenges

While cooling systems such as fans, liquid cooling, or heat pipes actively manage heat, the aluminum frame can still influence the efficiency of heat dissipation.

Here’s how:

- Contact interfaces: Aluminum frames must ensure consistent thermal contact with cooling components. Imperfect alignment between heat sinks and frame sections can lead to higher thermal resistance and inefficient cooling.

- Pathway to cooling: Aluminum must guide heat toward cooling components (e.g., heat pipes or thermal pads) to ensure heat is effectively transferred away from sensitive components.

In poorly designed systems, heat can build up in the wrong areas, reducing overall performance and hardware lifespan.

5. The Impact of Thermal Expansion on Structural Integrity

A lesser-known but critical factor in thermal path design is thermal expansion.

- Material stress: Aluminum expands and contracts with temperature fluctuations. This can introduce mechanical stress on the structure, leading to potential deformations, misalignments, or even component damage over time.

- Thermal fatigue: Components like heat sinks and connectors can suffer from fatigue when subjected to repetitive heating and cooling cycles, especially if the aluminum frame does not allow for proper movement or flexibility.

Therefore, frame geometry must account for expansion and contraction by allowing slight tolerance variations without affecting alignment.

6. Optimizing Aluminum Frame Design for Heat Flow

To maximize the thermal performance of aluminum in high-density AI systems, frame design must be carefully optimized around the following principles:

1. Enhance Heat Distribution

- Use multi-cavity designs to ensure heat is spread across a larger surface area.

- Integrate thermal bridges within the frame to help direct heat towards cooling zones.

2. Minimize Hotspots

- Avoid thin profiles where heat cannot dissipate easily.

- Ensure even thickness across the frame to maintain consistent conductivity.

3. Improve Component Mounting

- Ensure that heat-generating components like GPUs, processors, and cooling systems are aligned with the aluminum frame for direct thermal contact.

- Use thermal pads or conductive materials where necessary to fill gaps and improve contact.

4. Accommodate Thermal Expansion

- Allow for tolerances that enable slight movement during thermal cycling without compromising structural integrity.

7. Practical Examples of Aluminum’s Role in AI Systems

Let’s look at a practical AI server rack example:

- Rack Design: Aluminum extrusions form the primary structure of the rack. The frame includes horizontal extrusions to help distribute heat from the GPUs to vertical extrusions that guide the heat towards heat sinks.

- Heat Dissipation: Heat from the GPUs is conducted through the frame’s aluminum sections, where it is then transferred to heat pipes integrated along the frame.

- Cooling Efficiency: The frame is designed to maximize airflow, with aluminum rails allowing fans to push hot air away from the components, keeping the system within thermal limits.

In this design, aluminum performs as both the structural element and a key thermal conductor, optimizing the system’s ability to manage heat effectively.

8. Thermal Path Design: A System-Level Approach

Thermal path design is not just about material properties or individual components—it is about system-level thinking.

By using aluminum as both a structural and thermal component, engineers can ensure that:

- Heat is dissipated evenly across the rack

- Hotspots are minimized

- System reliability and lifespan are maximized

Designing an aluminum frame to handle heat flow effectively means taking into account geometry, material properties, cooling integration, and thermal expansion, all while maintaining structural integrity.

Aluminum’s role in AI systems goes beyond its traditional structural purpose. In high-density systems, aluminum frames mediate heat flow, guiding thermal energy from components to cooling systems.

By optimizing thermal path design, engineers can ensure:

- Efficient heat dissipation

- Improved system reliability

- Enhanced long-term performance

Understanding how aluminum structures affect heat flow is crucial for building sustainable, scalable AI systems that can meet the growing thermal demands of tomorrow’s technology.