As AI computing density continues to rise, the aluminum frame is no longer just a passive mechanical structure. In high-density AI racks, aluminum frames actively influence thermal behavior, structural stability, assembly efficiency, and long-term system reliability.

This article explains the design logic behind aluminum frames used in high-density AI racks—not from a marketing perspective, but from an engineering decision-making standpoint.

1. Why Aluminum Frames Matter More in High-Density AI Systems

Traditional server racks were designed around moderate power density and predictable airflow. AI racks are different:

- Higher GPU density

- Heavier localized loads

- More aggressive thermal gradients

- Tighter assembly tolerances

In this environment, aluminum frames are no longer interchangeable components. They become load-bearing, heat-influencing, tolerance-sensitive system elements.

The key design challenge is not “using aluminum,” but choosing the right aluminum structure logic.

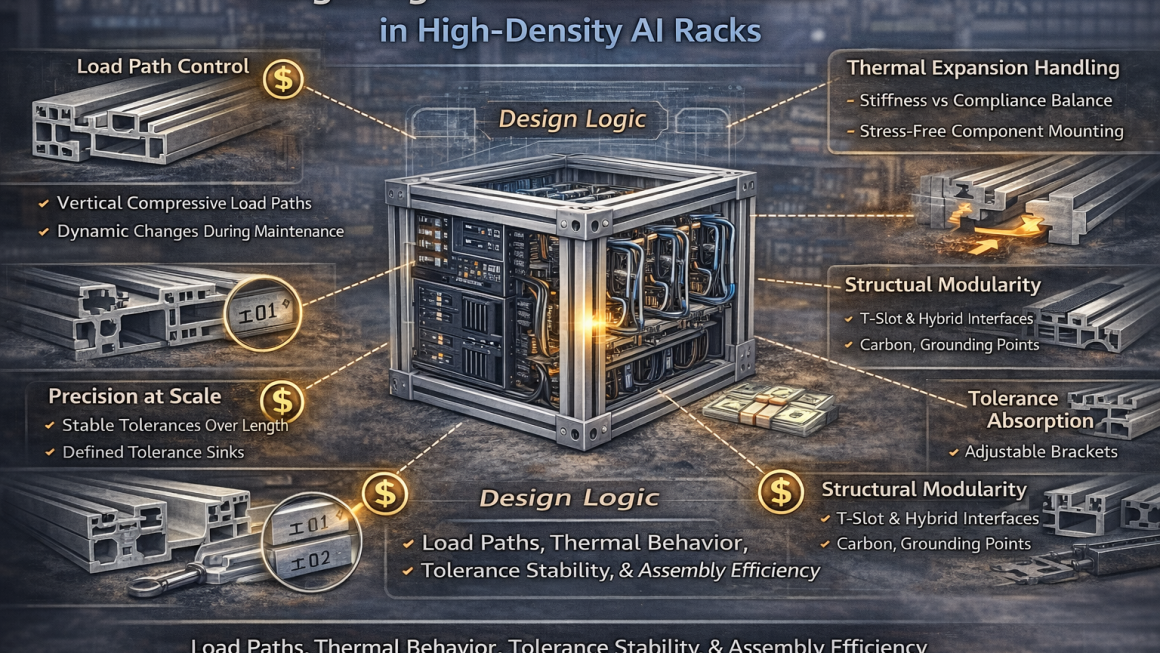

2. Structural Load Logic: Static Load vs Dynamic Load

High-density AI racks introduce non-uniform load distribution:

- GPUs concentrate weight in specific vertical zones

- Liquid cooling systems add asymmetric mass

- Maintenance cycles introduce repeated dynamic loads

Design implication:

Aluminum frame design must consider:

- Vertical compressive load paths (rack stacking)

- Shear resistance during transport and installation

- Fatigue behavior under vibration and service cycles

Extruded aluminum profiles with internal ribs often outperform simple hollow sections—not because they are “stronger,” but because they control deformation paths more predictably.

3. Thermal-Mechanical Coupling: The Hidden Constraint

In high-density AI racks, thermal and mechanical design are inseparable.

Aluminum’s high thermal conductivity is an advantage—but it also introduces:

- Differential thermal expansion

- Frame distortion under sustained heat loads

- Stress transfer to mounted components

Engineers must balance:

- Section thickness vs thermal mass

- Stiffness vs expansion tolerance

- Structural rigidity vs thermal compliance

This is why over-designing stiffness can actually reduce system reliability in AI racks.

4. Profile Geometry: Why Shape Matters More Than Alloy

For AI racks, the profile shape often matters more than the alloy grade.

Common design objectives include:

- Maximizing stiffness-to-weight ratio

- Integrating cable paths and airflow gaps

- Supporting modular expansion

Typical high-density designs favor:

- Multi-cavity extrusions

- T-slot or hybrid slot profiles

- Profiles optimized for directional stiffness

A well-designed profile reduces secondary machining, lowers assembly errors, and improves long-term dimensional stability.

5. Tolerance Stack-Up: The Silent Failure Mode

High-density racks amplify tolerance problems.

A ±0.2 mm deviation at one joint can become:

- Misaligned GPU trays

- Uneven airflow channels

- Assembly stress locked into the structure

Smart frame design includes:

- Defined datum surfaces

- Adjustable connection zones

- Controlled tolerance “sinks”

The aluminum frame must absorb manufacturing variation, not transfer it downstream.

6. Modularity vs Rigidity: A Deliberate Trade-Off

AI infrastructure evolves fast. Aluminum frames must support:

- Rapid configuration changes

- Different cooling architectures

- Future hardware generations

However, excessive modularity can reduce structural coherence.

Good design logic answers:

- Which joints must be rigid?

- Which interfaces should remain adjustable?

- Where is modularity truly needed—and where is it just complexity?

The best aluminum frames are selectively modular, not universally flexible.

7. Assembly Logic: Engineering for Humans, Not Just CAD

High-density AI racks are often assembled under time pressure.

Frame design must consider:

- Assembly sequence

- Tool access

- Error-proofing

Extrusion-based systems with repeatable interfaces reduce:

- Assembly time

- Field errors

- Rework risk

This is where aluminum’s machinability and extrusion flexibility become strategic advantages—not just cost factors.

8. Cost Is a System Property, Not a Material Price

A common mistake is optimizing aluminum frame cost per kilogram.

In reality, total cost is influenced by:

- Machining complexity

- Assembly labor

- Yield loss from tolerance mismatch

- Field maintenance and upgrades

A slightly more expensive profile often reduces total system cost across the rack’s lifecycle.

9. Aluminum Frames as System Interfaces

In AI racks, aluminum frames increasingly serve as:

- Thermal interfaces

- Grounding paths

- Mounting platforms for hybrid materials

This requires forward-looking design logic that anticipates:

- Carbon-based thermal components

- Composite panels

- EMI and grounding requirements

Aluminum becomes the structural mediator, not just the skeleton.

10. Design Logic Summary

High-density AI rack aluminum frames succeed when they:

- Control load paths, not just strength

- Balance stiffness with thermal compliance

- Manage tolerance instead of ignoring it

- Support modularity without structural chaos

- Optimize system cost, not material cost

Aluminum remains the backbone of AI hardware—not because it is traditional, but because it is engineerable.

Closing Thought

The future of AI hardware will not be decided by exotic materials alone. It will be shaped by how well engineers design familiar materials—like aluminum—into intelligent systems.

That is where aluminum frames truly earn their place in high-density AI infrastructure.