Engineering Questions That Actually Matter in AI Data Centers

We focus on the aluminum-related decisions engineers worry about — long before procurement.

When performance, cost, and manufacturability collide.

Aluminum profile selection for AI server racks

Structural vs thermal trade-offs in AI infrastructure

Weight, stiffness, airflow, and assembly constraints

What fails first — and why.

Common aluminum-related failures in AI data centers

Corrosion, deformation, vibration, and fatigue risks

Design details that look fine on drawings but fail on site

What drawings don’t tell you.

What engineers should know about aluminum extrusion tolerances

CNC, surface treatment, and consistency risks

Lead-time uncertainty in AI infrastructure aluminum components

How We Support AI Data Center Projects →

We don’t sell standard parts. We support engineering decisions and execution.

Early-Stage Design Alignment

Before drawings are frozen.

We work with engineering and infrastructure teams at the early design stage to clarify structural, thermal, and assembly requirements for aluminum components used in AI data centers.

Our role is to help identify feasible design directions — before costly revisions appear later in the project.

Design for Manufacturing (DFM) Support

Turning design intent into manufacturable reality.

We assist in reviewing aluminum designs from a manufacturability perspective, helping clients understand how extrusion tolerance, CNC capability, surface treatment, and assembly constraints affect real-world outcomes.

This reduces redesign cycles and unexpected production risks.

Supplier Capability Matching

Not every factory is right for AI infrastructure.

We maintain a vetted supplier network and help match each project with manufacturers whose technical capabilities, equipment, and process control align with the specific requirements of AI data center aluminum components.

Production feasibility always depends on supplier validation.

Traceable & Predictable Supply Chain

Clarity beats promises.

We focus on building supply chains that are transparent and predictable — with clear process steps, realistic lead times, and traceable production responsibility.

This helps engineering and procurement teams plan with confidence in fast-moving AI infrastructure projects.

Technical Documentation & Knowledge Support

Better decisions start with better information.

We provide material datasheets, process guidelines, and application notes compiled from supplier data and project experience — supporting informed engineering decisions without overstating performance claims.

- Our value is not in claiming capability — but in helping you understand what is feasible, realistic, and scalable.

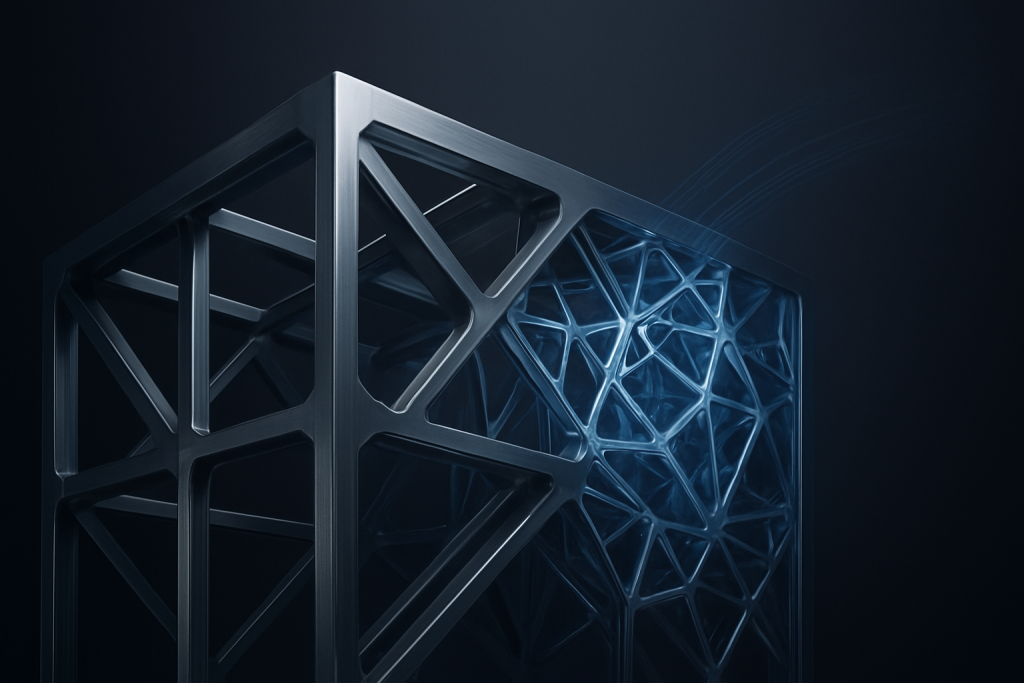

AI-Optimized Aluminum Structures

Engineering concepts leveraging AI-driven topology optimization and thermal simulation to support advanced aluminum frame and cooling designs

We support design and engineering of aluminum structures optimized for AI cooling and strength.

Key Highlights

High-strength, lightweight AI-optimized design

Improved thermal pathways and airflow distribution

Modular architecture for fast installation and expansion

Engineered for High-Performance Infrastructure

By combining aluminum’s natural advantages with AI-driven structural analysis, we unlock new performance levels for industrial and data center applications. Our AI-driven simulation tools are designed to support identification of efficient material distribution, improve predicted stiffness and thermal behavio.The result: structures that are stronger, cooler, and significantly more energy-efficient.

AI topology optimization

Precision manufacturing for high repeatability

Thermal and CFD simulation

Material efficiency and reduced cost per watt

Where Our Aluminum Structures Perform Best

Data Center Frames

Server Racks

Lightweight, modular frames engineered for high load and vibration control.

Optimized stiffness and cooling pathways for stable, high-density deployment.

Cooling Channels & Ducts

Custom Industrial Structures

AI-designed airflow paths improve thermal uniformity and reduce hot spots.

Tailored aluminum solutions for robotics, automation, and precision equipment.

Why Choose Aluminum4AI

Extreme Strength-to-Weight Ratio

Superior Thermal Conductivity

AI-optimized geometry enhances load performance while reducing mass.

Precision Manufacturing

High-tolerance CNC and extrusion ensure consistent performance.

Aluminum’s natural heat-dissipation ability amplified through AI analysis.

Modular & Scalable

Structures are designed for rapid deployment and easy expansion.

Sustainability

Aluminum is recyclable, energy-efficient, and aligned with low-carbon goals.

From AI Simulation to Ready-to-Deploy Structures

1. Requirement Analysis to inform design directions

2. AI Topology Optimization support

We evaluate mechanical load, heat flow, and installation constraints.

Our AI engine identifies the most efficient material layout.

3. Preparation for assembly and engineering verification

4. Precision Manufacturing

CFD and heat-mapping ensure optimal cooling performance.

CNC machining, extrusion, or hybrid methods deliver exact geometry.

5. Preparation for assembly and engineering verification

Every structure is tested for strength, vibration, and thermal reliability.

Data Centers

Telecom Infrastructure

High-Density Computing

Industrial Automation

Robotics & Machine Frames

Clean Energy Equipment

Build the Next Generation of Aluminum Structures

Whether you need a custom AI-optimized design or a ready-to-deploy frame, we support your full development cycle—from concept and simulation to manufacturing and assembly.